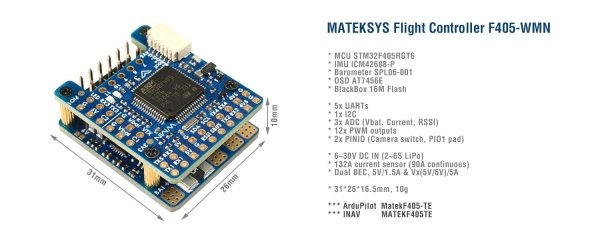

FC Specifications

- MCU: STM32F405RGT6, 168MHz , 1MB Flash

- IMU: ICM42688-P

- Baro: SPL06-001

- OSD: AT7456E

- Blackbox: 16M Flash

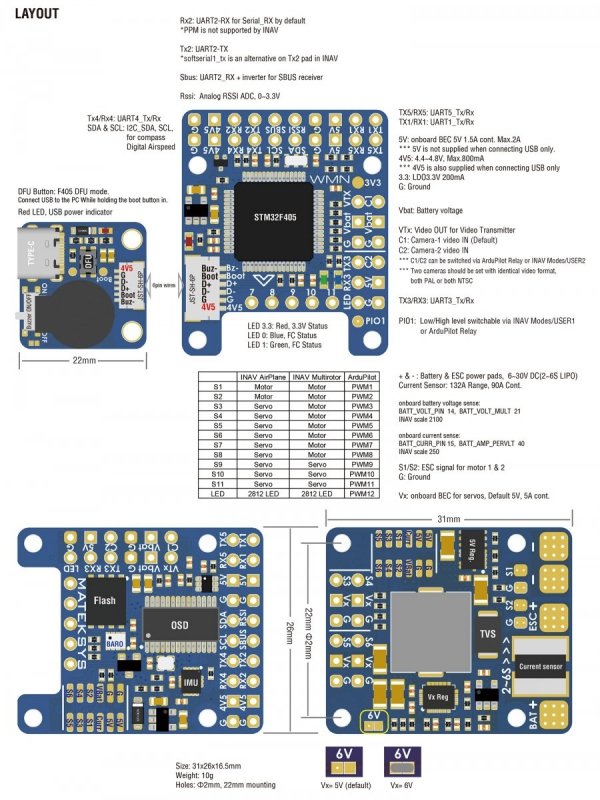

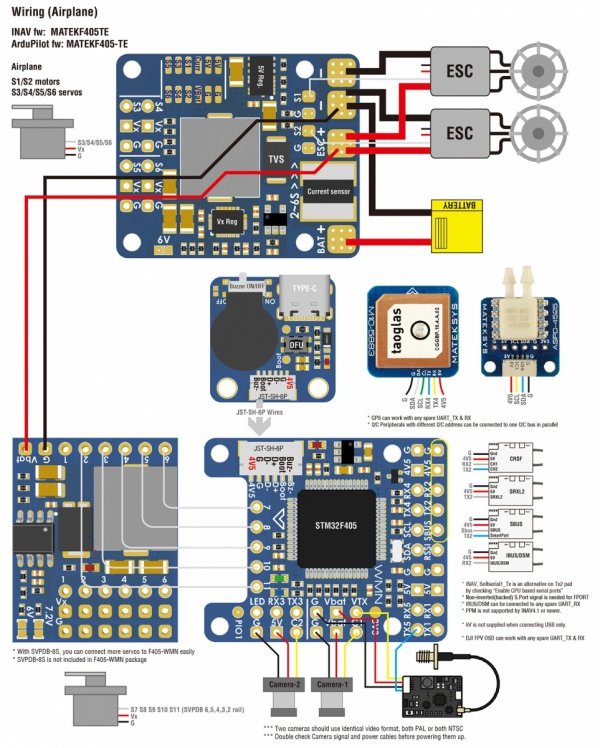

- 5x UARTs, 1x Softserial_Tx option(INAV)

- 12x PWM outputs

- 1x I2C

- 3x ADC (VBAT, Current, RSSI)

- 1x spare PINIO

- USB/Beep Extender with Type-C(USB2.0)

- Built in inverter on UART2-RX for SBUS input

- Switchable Dual Camera Inputs

Power

- 6~30V DC IN (2~6S LiPo)

- 132A Current Sense (INAV Scale 250, ArduPilot 40A/V)

- PDB/Current sense resistor: 90A continuous, 132A burst.

- BEC 5V 1.5A for FC & Peripherals

- BEC Vx 5A for servos, 5V/ 6V option

- Vbat for VTX and camera

- LDO 3.3V 200mA

- Battery Voltage Sensor: 1k:20k

FC Firmware

- ArduPilot: MatekF405-TE

- INAV: MATEKF405TE (INAV 5.0 or newer)

Physical

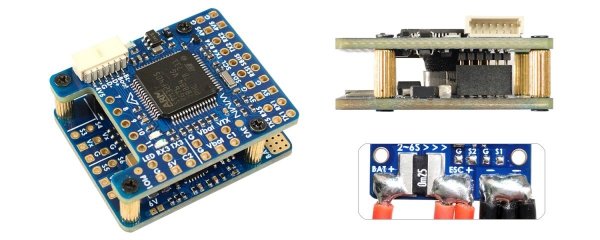

- Dimensions: 31 x 26 x 16.5 mm

- Mounting: 22 x 22mm, Φ2mm

- Weight: 10g

Including

- 1x F405-WMN

- 1x USB(Type-C)/Beep (Passive buzzer) Extender + 20cm JST-SH-6P to JST-SH-6P cable for USB extender.

- Dupont 2.54 pins (Board is shipped unsoldered)

INAV Mapping

| INAV MultiRotor | INAV Plane | ||||

| PWM | S1 | 5 V tolerant I/O | TIM8_CH4 | Motor | Motor |

| S2 | 5 V tolerant I/O | TIM8_CH3 | Motor | Motor | |

| S3 | 5 V tolerant I/O | TIM1_CH3N | Motor | Servo | |

| S4 | 5 V tolerant I/O | TIM1_CH1 | Motor | Servo | |

| S5 | 5 V tolerant I/O | TIM2_CH4 | Motor | Servo | |

| S6 | 5 V tolerant I/O | TIM2_CH3 | Motor | Servo | |

| S7 | 5 V tolerant I/O | TIM2_CH2 | Motor | Servo | |

| S8 | 5 V tolerant I/O | TIM2_CH1 | Motor | Servo | |

| S9 | 5 V tolerant I/O | TIM12_CH1 | Servo | Servo | |

| S10 | 5 V tolerant I/O | TIM13_CH1 | Servo | Servo | |

| S11 | 5 V tolerant I/O | TIM4_CH1 | Servo | Servo | |

| LED | 5 V tolerant I/O | TIM3_CH4 | 2812LED | 2812LED | |

| ADC | Vbat Pad | 1K:20K divider builtin 0~30V |

Vbat ADC ADC_CHANNEL_1 |

INAV voltage scale 2100 | |

| Curr pad | 0~3.3V | Current ADC ADC_CHANNEL_2 |

scale 150 | ||

| RSSI Pad | 0~3.3V | RSSI ADC ADC_CHANNEL_3 |

Analog RSSI | ||

| No Pad | AirS ADC ADC_CHANNEL_4 |

||||

| I2C | I2C1 | 5V tolerant I/O | Compass | QMC5883 / HMC5883 /MAG3110 / LIS3MDL | |

| OLED | 0.96″ | ||||

| onboard Barometer | SPL06-001 | ||||

| Digital Airspeed sensor | MS4525 | ||||

| Temperature sensor | |||||

| UART 5V tolerant I/O |

USB | USB | |||

| TX1 RX1 | 5V tolerant I/O | UART1 | USER | ||

| TX3 RX3 | UART3 | USER | |||

| TX4 RX4 | UART4 | USER | |||

| TX5 RX5 | UART5 | USER | |||

| No Pad | UART6 | – | |||

| TX2 RX2 SBUS |

5V tolerant I/O | UART2 | RC input/Receiver | ||

| Sbus pad | for SBUS receiver, Sbus pad = RX2+inverter | ||||

| RX2 pad | IBUS/DSM/PPM | ||||

| TX2 & RX2 | CRSF | ||||

| TX2 pad | SmartPort Telemetry | enable Softserial_Tx1 | |||

| TX2 pad | FPORT, uninverted S.Port/F.Port signal (hacked) | ||||

| TX2 pad | SRXL2 | ||||

PINIO

- PINIO1 /PIO1 pad, Low Level by default, Low/High level switchable by Mode-USER1

- PINIO2 is for camera input switch by Modes-USER2

Tips

- F405-WMN has INAV fw preloaded for QC

- Download INAV firmware 4.1.x from our website. Target MATEKF405TE is not listed in INAV configurator 4.x.x,

- You may download INAV fw 5.0 or newer directly from INAV configurator 5.x or newer.

Ardupilot Mapping

| ArduPilot | |||||

| PWM 5V tolerant I/O |

S1 | PWM1 GPIO50 | TIM8_CH4 | DMA/DShot | Group1 |

| S2 | PWM2 GPIO51 | TIM8_CH3 | DMA/DShot | ||

| S3 | PWM3 GPIO52 | TIM1_CH3N | DMA/DShot | Group2 | |

| S4 | PWM4 GPIO53 | TIM1_CH1 | DMA/DShot | ||

| S5 | PWM5 GPIO54 | TIM2_CH4 | DMA/DShot | Gourp3 | |

| S6 | PWM6 GPIO55 | TIM2_CH3 | DMA/DShot | ||

| S7 | PWM7 GPIO56 | TIM2_CH2 | DMA/DShot | ||

| S8 | PWM8 GPIO57 | TIM2_CH1 | DMA/DShot | ||

| S9 | PWM9 GPIO58 | TIM12_CH1 | NO DMA | Gourp4 | |

| S10 | PWM10 GPIO59 | TIM13_CH1 | NO DMA | Gourp5 | |

| S11 | PWM11 GPIO60 | TIM4_CH1 | NO DMA | Gourp6 | |

| LED pad | PWM12 GPIO61 | TIM3_CH4 | DMA/DShot | Gourp7 | |

| SERVO12_FUNCTION 120, NTF_LED_TYPES neopixel | |||||

| Mixing Dshot and normal PWM operation for outputs is restricted into groups, ie. enabling Dshot for an output in a group requires that ALL outputs in that group be configured and used as Dshot, rather than PWM outputs. If servo and motor are mixed in same group, make sure this group run lowest PWM frequency according to the servo specification. ie. Servo supports Max. 50Hz, ESC must run at 50Hz in this group. |

|||||

| ADC | Vbat Pad | 1K:20K divider builtin 0~30V |

Vbat ADC

onboard battery voltage |

BATT_VOLT_PIN BATT_VOLT_MULT |

14 21.0 |

| Curr pad | 0~3.3V | current sensor ADC

onboard current sense |

BATT_CURR_PIN BATT_AMP_PERVLT |

15 40 |

|

| RSSI Pad | 0~3.3V | RSSI ADC Analog RSSI |

RSSI_ANA_PIN RSSI_TYPE |

8 2 |

|

| – | – | – | – | – | |

| I2C | I2C1 | 5V tolerant I/O | Compass | COMPASS_AUTODEC | 1 |

| onboard Baro SPL06-001 | Address | 0x76 | |||

| Digital Airspeed I2C MS4525 DLVR-L10D |

ARSPD_BUS ARSPD_TYPE ARSPD_TYPE |

1 1 9 |

|||

| UART 5V tolerant I/O |

USB | USB | console | SERIAL0 | |

| TX1 RX1 | USART1 | with DMA | telem1 | SERIAL1 | |

| TX3 RX3 | USART3 | NO DMA | telem2 | SERIAL2 | |

| TX5 RX5 | UART5 | NO DMA | GPS1 *** | SERIAL3 | |

| TX4 RX4 | UART4 | NO DMA | GPS2 *** | SERIAL4 | |

| – | – | – | – | SERIAL5 | |

| TX2 RX2 SBUS |

USART2 | with DMA | RC input/Receiver | SERIAL6 | |

| RX2 | IBUS/DSM/PPM | BRD_ALT_CONFIG 0 Default |

|||

| Sbus pad | SBUS | ||||

| TX2 & RX2 | CRSF | BRD_ALT_CONFIG 1 SERIAL6_PROTOCOL 23 |

SERIAL6_OPTIONS 0 | ||

| TX2 | uninverted FPort (hacked) | SERIAL6_OPTIONS 4 | |||

| TX2 | SRXL2 | SERIAL6_OPTIONS 4 | |||

- *** If connecting just one GPS to UART4(TX4/RX4), pls set UART5 SERIAL3_PROTOCOL = -1 or non “5”. otherwise ArduPilot will stop searching for GPS during bootup if not found on the first port(SERIAL3, UART5) configured for GPS protocol.

- If sending highspeed serial data (eg. 921600 baud) to the board, use USART1(Serial1) or USART2(Serial6).

Frsky Smartport Telemetry

- non-inverted (hacked) S.Port signal

- any spare Uart_TX

- SERIALx_BAUD 57

- SERIALx_OPTIONS 7

- SERIALx_PROTOCOL 4 or 10(for yaapu)

DJI FPV OSD (ArduPilot 4.1)

- OSD_TYPE = 3

- SERIALx_PROTOCOL = 33

- MSP_OPTIONS = 0 (polling mode)

Relay(PINIO)

- PINIO1, PIO1 pad, Low Level by default

- PINIO2, Camera switch, C1 ON by default

# GPIOs

- PA4 PINIO1 OUTPUT GPIO(81) LOW //PIO1 pad

- PB5 PINIO2 OUTPUT GPIO(82) LOW //camera switch

# RCx_OPTION: RC input option

- 28 Relay On/Off

- 34 Relay2 On/Off

- 35 Relay3 On/Off

- 36 Relay4 On/Off

e.g.

- RELAY_PIN 81 //PIO1 GPIO

- RC7_OPTION 28 //Relay On/Off, Use CH7 of Transmitter to control PIO1 Low/High Level

- RELAY_PIN2 82 //Camera switch GPIO

- RC8_OPTION 34 //Relay2 On/Off, Use CH8 of Transmitter to control high/low level on PB5 pad

The configured feature will be triggered when the auxiliary switch’s pwm value becomes higher than 1800. It will be deactivated when the value falls below 1200.

Check the pwm value sent from the transmitter when the switch is high and low using the Mission Planner’s Initial Setup >> Mandatory Hardware >> Radio Calibration screen. If it does not climb higher than 1800 or lower than 1200, it is best to adjust the servo end points in the transmitter.

Polecamy

MATEK H743-WLITE Flight Controller

563,00

PLN

MATEK H743-MINI V3 Flight Controller

543,00

PLN

MATEK AP Periph CAN Node L431

99,00

PLN

MATEK F722-mini SE F7 Flight Controller

364,00

PLN

Matek Analog Pixel OSD module

99,00

PLN

Matek M10 GPS QMC5883 Compass for FPV

200,00

PLN

MATEK H743-SLIM V3 Flight Controller

563,00

PLN

MATEK F411-WTE Flight Controller

280,00

PLN

MATEK F405-TE OSD PDB Flight Controller

376,00

PLN